Achitex Minerva Group

over 70 years of experience at customers' service.

The Achitex Minerva Group is a dynamic "pocket-sized multinational" which has successfully made textile chemicals its core business.

It has been manufacturing and selling chemicals for all phases of textile processing for over 70 years, although over time it has differentiated its operations to create product ranges for the paper cone, glass fibre and construction industries.

Today it is one of the leading European players in the production of water-based pigment dispersions for the textile, coatings, adhesive tape, scouring fibre and flexographic printing industries.

Research, development, customer care, quality and environmental awareness are key factors for the competitiveness of the Group and of the Industry which it serves, and make Achitex Minerva a reliable partner for leading chemicals companies in over 80 countries worldwide.

Find out more

News

TEXTILE CHEMISTRY

Achitex Minerva textile sector includes a portfolio of chemical products destined to all phases of the textile finishing process, from spinning to printing, both continuous and discontinuous.

TEXTILE PRINTING

The Group produces and sells high-quality, high-performance and eco-compatible products for continuous and discontinuous textile printing. The wide range allows customized solutions with excellent quality results.

PIGMENTAL DISPERSIONS

Achitex Minerva is a European leader in the formulation of water-based pigment dispersions, which find application in textiles and in sectors such as the paper industry, adhesive tapes, scouring fibres, agrochemicals...

SPECIAL LINES

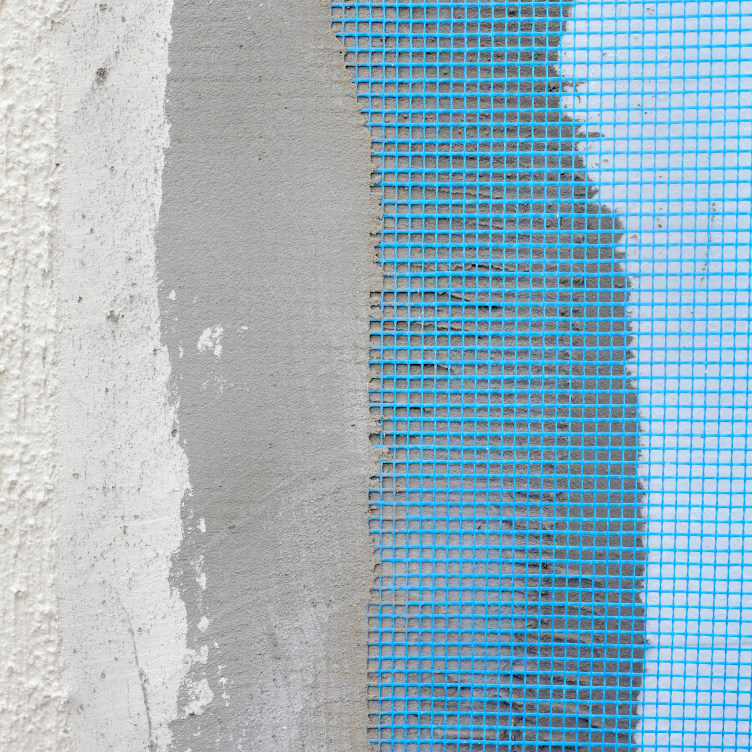

The Group has specialized in some non-textile areas, such as sizing for fiberglass, glues for paper cones and a range intended for the protection and renewal of building materials.